The APQP, or Advanced Product Quality Planning, is a proven approach for developing a new product to be made in high volume and under strict quality, timing, and cost requirements.

It was developed by the North American automotive industry (virtually all tier-1 suppliers of car parts have to implement this approach.) It has also been adopted in other settings with similarly comprehensive requirements, with great success. (Note: for low- or medium-volume productions, a simpler quality plan is usually more appropriate).

Adding some structure to the design & development phase

I have heard many people tell me “design and development are not linear, so it is hard to formalize”. That’s very true, but there are ways to manage it as a series of process steps with gate reviews and required deliverables.

In ISO 9001:2015, clause 8.3 reads “The organization shall establish, implement and maintain a design and development process that is appropriate to ensure the subsequent provision of products and services.” And it defines requirements for:

- Planning

- Inputs

- Controls

- Outputs

- Management of changes

The APQP follows the same structured approach but goes more in-depth (remember, it is called the ‘advanced’ product quality planning).

Large car manufacturers have formalized a set of process steps they expect their suppliers to follow. It was developed by the AIAG, an industry group serving mostly the needs of GM, Ford, and Chrysler.

In short, the objective is to maximize the likelihood that the new product will fulfil the customer’s requirements. In other words, no bad surprises are allowed! If one part can’t be used and an entire automotive plant has to stop, the cost is close to 50,000 USD a minute…

What activities and milestones make up Advanced Product Quality Planning (APQP)?

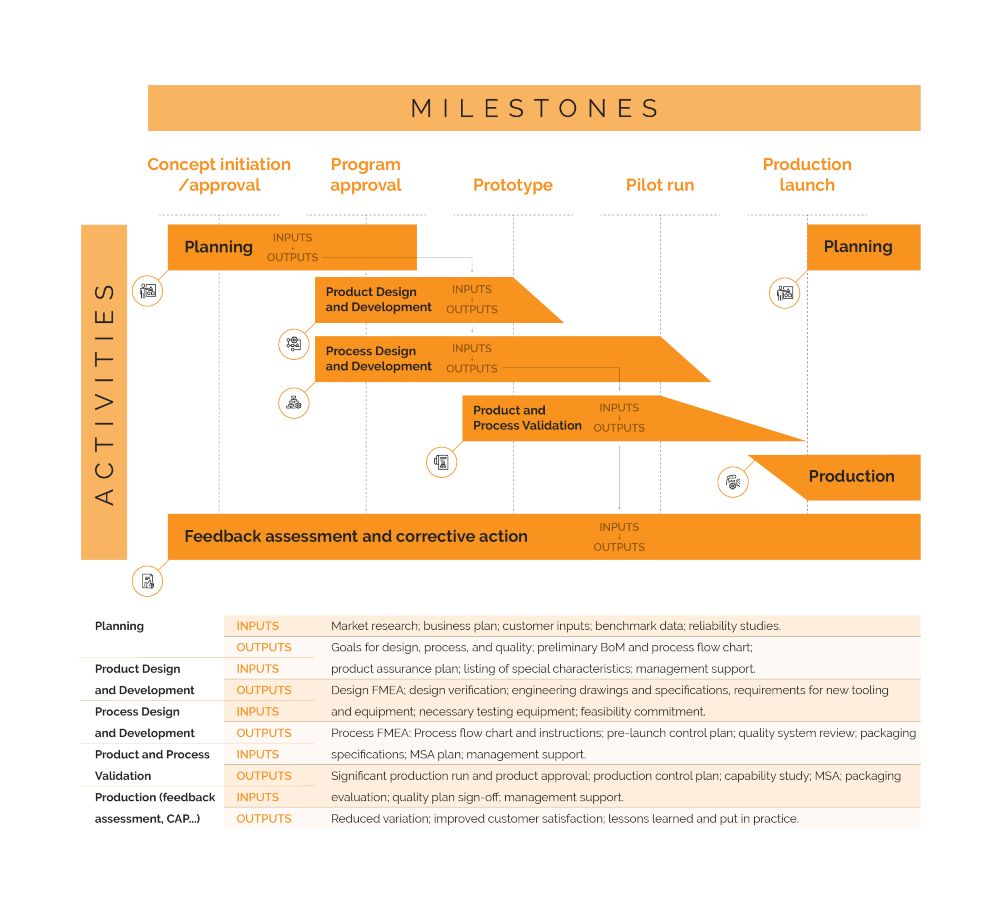

It is usually summarized as follows:

The 6 activities can be outlined as below:

1. Planning

- 1.1 Inputs: customer suggestions/requirements, historical information about similar products, the company’s objectives…

- 1.2 Outputs: a detailed plan that includes goals for design and for quality/reliability, preliminary process information, and preliminary product features.

2. Product design & development

- 2.1 Input: step 1.2.

- 2.2 Outputs: design FMEA, DFM analysis, drawings and first prototypes, material specifications, reviews and verifications, requirements for testing equipment….

3. Process design & development

4. Product & process validation

- 4.1 Input: steps 1.2, 2,2, and 3.2.

- 4.2 Outputs: a pilot production run that went through the process steps outlined above and went through testing & inspection, and detailed evaluation of the results.

5 and 6. Mass production + feedback, corrective actions…

5.1 Input: steps 1.2, 2,2, 3.2, and 4.2.

5.2 Outputs: application of what was learned in step 4 to get closer to the goals of step 1. The objective is to be ready for production launch.

The time to develop a new part or product is limited

As you can see in the above graph, some activities must take place at the same time. The product designers don’t “send drawings over the wall” to manufacturing people who only then discover what they have to make.

Many of the product design and process design activities take place concurrently. It is important to develop a part/product that can be manufactured and tested in a way that reaches the quality, cost, schedule, and safety objectives in a consistent manner.

As the process gets developed, it needs to be validated as early as possible. In the beginning, it can involve cheap mockups (with cardboard figures, or even simply drawing with chalk on a parking lot), and as time passes the engineers go more and more into the details, culminating with pre-production pilot runs. The people (training), the equipment, the materials, and the measurement methods, all have to come together and demonstrate production readiness.

Then comes the launch, with a progressive increase in the pace. The work is not over at that point, as there is usually a long list of production issues and ideas for improvement to work through.

The customer side of Advanced Product Quality Planning: the PPAP

Not all manufacturers want to do all the engineering required to comply with the Advanced Product Quality Planning approach. The temptation to skip steps and go straight into production (at higher risk) can be quite strong…

How does a customer monitor whether a supplier applies the APQP? They simply request and approve the deliverables (e.g. outputs) of the APQP — which is commonly called PPAP (Production Part Approval Process).

Note: to be accurate, the PPAP does not include all the APQP’s deliverables, since the APQP does not stop on the day of production launch. It keeps going, as there is often a lot to do after launch to keep improving the processes.

There is a manual for the PPAP (again, from the AIAG group in North America). And, just like APQP, that same approach is used in many industries.

An example of an important tool: Measurement system analysis (MSA)

Without a good measurement system, all data are subject to suspicion. Different inspectors and/or gauges find different values. The supplier and their customer can’t see eye to eye when they discuss quality data. Not good.

When we do a PPAP review for a buyer, here are the questions we generally look at when it comes to MSA:

- Was MSA applied to all critical measurement processes?

- Were sampling size and data quantity sufficient? How were they defined?

- Was the resolution of the device considered?

- Was repeatability considered?

- Was reproducibility considered?

- Was gage R&R calculated?

- When was the latest MSA study held? Is it done in a regular manner?

- Are the %R&R and %PT <10%?

- Is the number of distinct categories >5?

- Was the result of the gage R&R compared with the control plan gages?

This sounds like a lot of heavy statistics, but some very common software (e.g. Minitab) handles this well.

And yet, when we look at the way tier-1 car part makers do their APQP in China, we often find a lot of data that were just made up. It can be hard for the customer to detect all those situations. In the end, it is the manufacturer that suffers through customer complaints, chargebacks, and so on…

APQP is considered a “core tool”

From my observations, all tier-1 suppliers to American and European carmakers have to be IATF 16949 certified. That standard requires the use of APQP. There is no way around it.

So, the question is, how about your new product development process?

I believe most importers who develop custom-made products could get a lot of benefits from such a structured approach. Naturally, it requires working closely with the manufacturer and understanding their processes, and that can be difficult. But following this discipline only increases the chances of success.

*****

Have you set up an approach that makes sense for your needs (with the right level of preventive systems)? Has it allowed you to reduce quality and timing issues significantly once the goods get into mass production?

Editor’s note: This post was originally published in 2015 and has been updated and republished with new content in July 2020 and October 2022.

Get expert help to improve YOUR product quality from suppliers in China or Vietnam. Read: Quality Assurance In China Or Vietnam For Beginners

Grab your free copy of Sofeast’s eBook and learn the common traps new importers from China or Vietnam fall into, and how to avoid or overcome them in order to get the best possible production results. It also outlines a proven quality assurance strategy that you can follow in order to have better control over your product quality, covering:

- Finding Suitable Suppliers

- Defining your Requirements before Production Starts

- Don’t Skip the New Product Introduction Process

- Regular Quality Inspections (Trust but Verify)

- Tying Payments to Quality Approvals

Sounds good? Hit the button below to get your copy now: