Basic Info.

Model NO.

YP-496

Standard

DIN, ASTM, GOST, GB, JIS, ANSI, BS

Customized

Customized

Material

Peek

Application

Medical Industry

Tolerance

+- 0.001

Surface Treatment

Polishing

Produced by

CNC Machining Center

Delivery Date

7-15 Days

Product Name

Machined Peek Turning Parts

Transport Package

Carton Box

Specification

customized

Trademark

Youngparts

Origin

China

HS Code

7616991090

Production Capacity

500000PCS/Year

Product Description

Quality Control and Perfect Surface Finish for PEEK CNC Machining Parts

High precision CNC parts strictly according to customers' drawing, packing and quality demands

Tolerance: +/-0.005mm

100% inspection during production and final to guarantee quality

10 years experienced engineers and workers

Fast and timely delivery. Speedy & professional service

Offer with professional consultations in designing of new parts to save cost.

Quality assurance in accordance to ISO9001

| Material | Stainless Steel | SUS201,SUS303,SUS304,SUS316,SUS416,SUS420,17-4PH,SUS440C | |

| Steel | Q235,C20,C45(K1045),1214,1215 | ||

| Copper | C36000(C26800),C37700(HPb59),C38500(HPb58),C27200(CuZn37),C28000(CuZn40/H62),C3604, C51000, C52100, C54400,CuSn8 | ||

| Alumina | AL2024,AL5754(Almg3),AL5083,AL6061,AL6063,AL5052,AL7075 | ||

| Alloy Steel | SCM435,10B21 | ||

| Plastic | PA6,PA66,PP,PC,POM,FR4,ABS,Acrylic | ||

| Machining Processes | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe High precision 5-Axis turning-milling combined machining, CNC milling and turning, drilling, grinding, stamping, tapping, bending |

||

| Finish | Heat treatment, powder coating, electroplating, spraying, painting, polishing, deburring, wire drawing/brushed, anodizing, chrome plating, nickel plating, tin plating, silver plating, gold plating, galvanizing, blackening etc. | ||

| Dimensions | Customized | ||

| Tolerance | ±0.005mm | ||

| Drawing Format | PDF/JPEG/AI/PSD/CAD/Dwg/Step/LGS | ||

| MOQ | Negotiable | ||

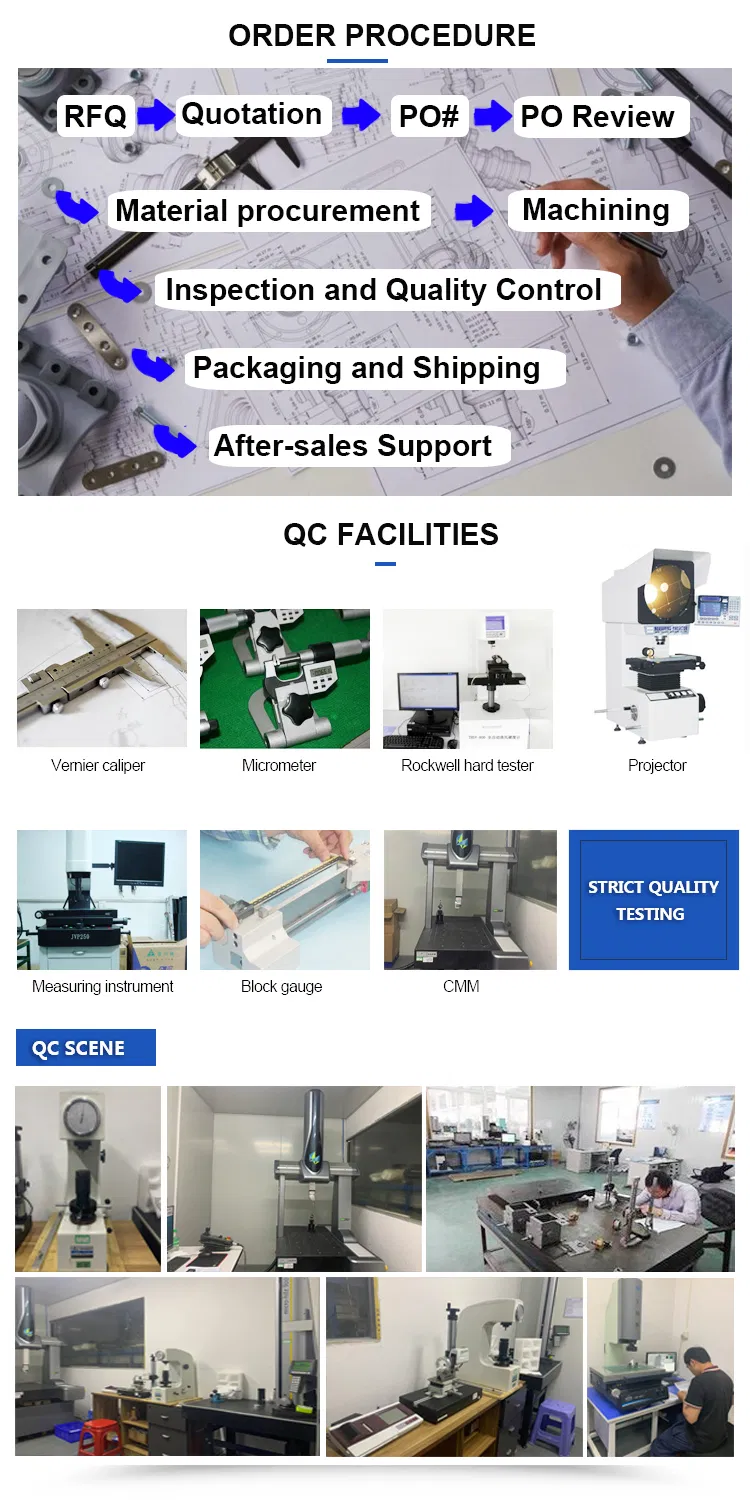

| QC Policy | 100% inspection and random inspection before shipment, with QC passed label | ||

| Stardard | Materials and surface treatment comply with RoHS/Reach Directives | ||

| Testing Equipments | CMM, Projector, Pull Tester, Automatic Optical Inspector, Salt Spray Tester, Durometer, Tensile Machine, height gauge, micrometer, plug gauge, thread Gauges, digital caliper and etc. | ||

| Application | Automotives, Optical instrument, medical device, industrial machine, automobile, electric appliance, robot, computers, tele-communication, electronic device, digital communication, UAV, aerospace, bicycle, pneumatic tools, hydraulic and other industries, | ||

| Packaging | PE bags or bubble bags, boxes, cartons, pallet, standard carton or plastic tray, sponge tray, cardboard tray or as per customers' requirements | ||

| Trade Terms | EXW, FOB, CIF, As per customers' request | ||

| Payment Terms | Paypal or Western Union for sample orders; Larger amount by T/T with 30% as deposit,70% before shipment | ||

| Delivery Time | Within 15-20 working days after deposit or payment received | ||

| Shipping Ports | FOB Dongguan, FOB Shenzhen, FOB Hongkong | ||

Factory Order Procudure

Our Advantage:

Our Advantage:

Our Packaging

Our Packaging

Our Shipping Methods

Our Shipping Methods